SIGNATURE PROJECT ARCHIVEMENTS

Project name: INPEX ICHTHYS Project: THE GAS EXPORT PIPELINE (GEP)

|

|

|

|

|

|

|

Client: |

Inpex Operations Australia Pty Ltd. |

Year: |

2012-currently on going. |

Service: |

Mill surveillance and monitoring of Plate inspection, plate loading, mill surveillance of pipe fabrication and inspection, pipe loading the pipe production for The 889 km Ichthys gas export pipeline. |

Project name: Tubular Bell InterConnect Project

|

|

Mill surveillance for billet heating for seamless pipe |

Mill surveillance for pipe rolling of seamless pipe |

Client: |

Williams Field Services Gulf Coast Company, LP |

Year: |

2012 Currently on-going |

Service: |

Mill surveillance and witness mechanical tastings for API 5L, PSL2 X65Q , DNV-OS-F101, Seamless Line pipe for Non Sour Service. Approximately 204,000 Ft at Sumitomo Metal Ind. (SMI) Wakayama works and Bend pipes at DHF Chiba Works Japan |

Project name: APLNG Upstream Phase 1 Trunk Line

|

SAW UOE pipes at pipe Yard before shipment |

|

Client: |

AUSTRALIA PACIFIC LNG Pty. Ltd. |

Year: |

2011-2012 Currently on-going |

Service: |

Quality surveillance activities, witness manufacturing procedure qualification testing, mechanical testing for SAW UOE Line pipe and ERW Line pipe API 5L X70 OD (1,067mm-762mm) x WT (13.34-22.4mm) x 555km at NSC Kimitsu Works |

Project name: Al- Khaleej Gas project Phase 2

|

Client: |

Exxon Mobil Middle East Gas Marketing Limited |

Year: |

2010 |

Service: |

Monitoring of Welding and NDT inspection for Amine Absorber at IHI Yokohama Plant |

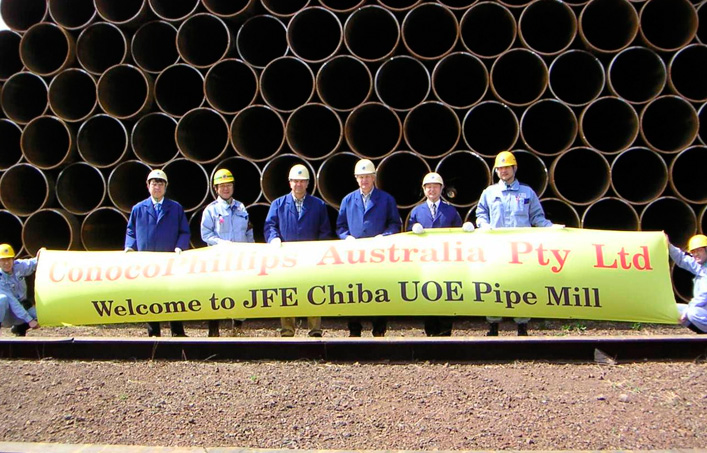

Project name: ConocoPhillips Australia Pty Ltd

|

|

Final inspection of Seamless pipe |

Loading surveillance of Seamless pipe |

Client: |

ConocoPhillips |

Year: |

2009-2010 |

Service: |

Seamless Tubular with Heat treatment and Premium connections |

Project name: Al- Khaleej Gas project Phase 2.

|

Client: |

Exxon Mobil Middle East Gas Marketing Limited |

Year: |

2007 |

Service: |

Witness functional acceptance testing for Lube Oil console unit at Mituzu Sangyo |

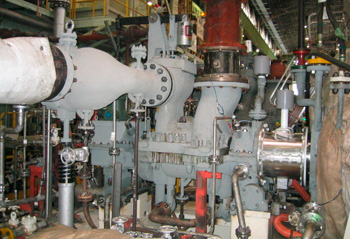

Project name: Ras Gas Onshore Expansion Project

|

|

Total Run out for Fuel Gas HP Compressor. |

General view of Spent regeneration gas recycle |

Client: |

ExxonMobil /Ras Laffan Liquefied Natural Gas Company Limited |

Year: |

2007 |

Service: |

Monitoring of inspection and witness performance tests for Steam turbine for off |

Project name: Bayu Darwin Project

|

Client: |

ConocoPhillips Australia Pty Ltd |

Year: |

2004-2005 |

Service: |

Mill surveillance and monitoring of Plate inspection, plate loading, mill surveillance of pipe fabrication and inspection, pipe loading the pipe production for 500Km pipe line, API 5L Forty-second edition X65 PSL2

O.D.660.0 mm x W.T.20.1 mm |