WHAT WE DO

Neco Q.A. have performed independent inspections, surveillance, monitoring product materials, witness of mechanical testing, non-destructive testing, dimensional inspections, as well as confirm the results of manufacturer’s test. We also have expedited projects and have delivered Quality Auditing services.

We can make sure your product meets the specified requirements from start to finish.

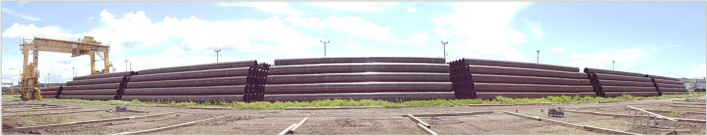

NECO’s inspector team for INPEX ICHTHYS PROJECT

WE SPECIALISE IN

- Comprehensive inspection

- Mechanical tests

- Nondestructive tests

- Performance tests

- Monitoring

- Audits

- Consulting

- Expediting

- Material verification

- Verifying dimensional measurements

- Endorsement of manufacturer’s test records and report

- Expediting projects

- Enhance the reporting process

Neco Q.A. have performed surveillance services on behalf of the client during the manufacturing, testing and loading of materials and equipment such as SAW Line pipe and OCTG product consignments from the manufactures and will perform the works in accordance with the contract scope and as formally instructed by the client representative for the product production and inspections ‘package’.

All Inspection personnel will be the client approved and project inducted prior to mobilization to the pipe mill workplace.

Only suitably qualified and experienced personnel will be engaged for the project assignment. QC Inspection Supervisors will be interviewed and approved by clients prior to engagement.

Surveillance Scope of Services

- 1 Pre Production Reviews and Meetings Phase

- 2 Manufacturing Trials and MPQT events

- 3 Pipe products Manufacture, Test, and Certification

- 4 Manufacturer Dossier Records review and Endorsement

- 5 Product Consignment Release and Loading

Sub-Merged arc Welding pipes at the pipe yard (before loading)

Pre-Production and MPQT Surveillance

The following MPQT Surveillance responsibilities will be undertaken on behalf of client in all production locations at the commencement of manufacture of DSAW Line pipe and OCTG products

- Review and comments to the Pipe mill MPS,MPQT, ITP, and Procedure documents

- Neco Q.A. Team Supervisor attendance to Pre-Production and Pre Inspection Meetings

- Confirm with the client’s representative the QC team make up and inspector postings for each facility

- Attend Steel making and laboratory for MPQT Test and analysis certification

- Verify MPQT production Test Equipment calibrations

- Plate rolling procedure review and test plate production witnessing

- MPQT Pipe manufacture and hydro test and NDE process witnessing

- MPQT Pipe test sample selection and subsequent mechanical test witnessing

- MPQT Records review and certification endorsements

- Provision of full MPQT surveillance report

DSAW Pipe and OCTG Production Surveillance

Key responsibility is to verify the implementation of the quality requirements as agreed within the approved MPS and ITP documents.

In Process DSAW and CRA OCTG production Surveillance will involve assignment of the full surveillance teams to all production shifts for Inspection and Test Plan (ITP) implementation throughout Production, Testing, and Certification.

Surveillance Team

The team make up is dependent on the manufacturers applied QC activity for the project order. This varies by order, by pipe mill, and by specification or code requirements would be finalized and communicated to manufacturer during the Pre Award audit and Pre Inspection formalities.

Key Surveillance Documents

The working documents for the Quality Surveillance assignment at each facility will be the Company approved Inspection Test Plans (ITP) and the Manufacturer Procedure Specification (MPS)for the relevant Purchase Orders which will list all activities from Kick Off Meetings through to final acceptance of MDR dossier packages after the release and dispatch of products.

Ship Loading Surveillance

Ship loading surveillance will require a team to oversee the following aspects of the ship loading performed at the port storage and ship berthing facility.

- 1Verification of ''Cargo Readiness'' status per each consignment.

- 2Review and endorse Test Certification for relevant materials.

- 3Verify bulk storage conditions and consignment traceability.

- 4Perform monitoring of Road, Rail or inland marine transportation.

- 5Liaise with suppliers transport and logistics department and MWS.

- 6Attend load out meeting - Joint review of approved stowage plan

- 7Conduct inspection of hull internal condition and chocking materials.

- 8Kick-off meeting with Client’s coordinator and load out inspectors.

- 9Verify that stowage and securement methods are compliant with stowage plan.

- 10Verify the compliance of packaging crating and labelling and loading of OCTG consignments.

- 11Report and record all damage and contamination incidents - quarantine defective. Goods for repair or replacement.

- 12Verify supplier tally documents for ‘Sail Away' approval.